ore ball mill grinding specification

2023-11-05T15:11:44+00:00

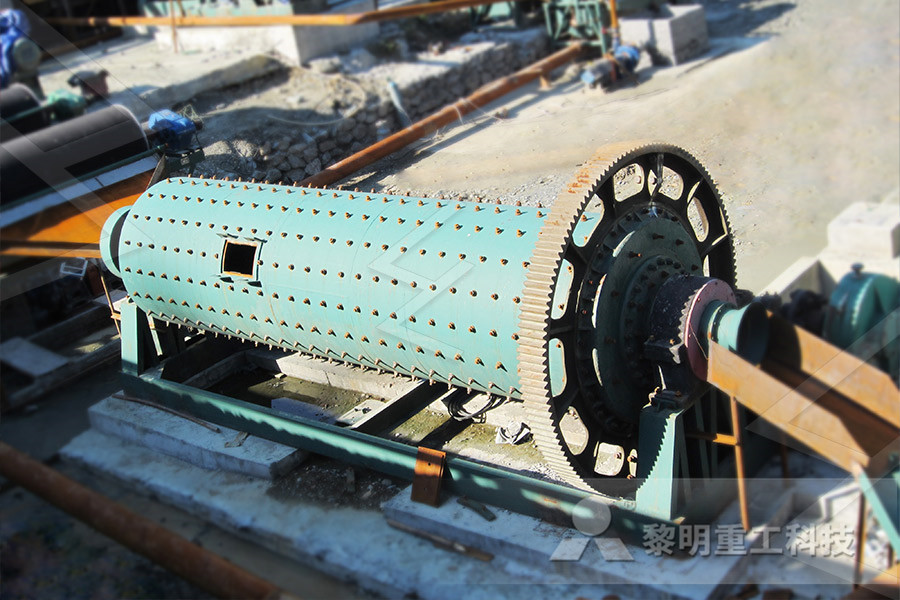

Ball Mill Used in Minerals Processing Plant

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as Specification (mm): Φ750×750Φ2700×4500 It is used for processing various grindable mineral materials, nonferrous metal mineral processing, new building materials, etc : info@ballmillssupplierBuy Ore Ball Mill for Mineral Processing Iron2023年9月10日 The amount of ore fed into the mill for each experiment was 200 g and the mass concentration of the mill was 67%, both of which were constant parameters Firstly, Ceramic Grinding Kinetics of Fine Magnetite Ores in the Batch Ball Mill

An experimental study on the ultrafine grinding of gypsum ore

2016年4月1日 In this study, batch grinding tests of gypsum ore were performed using a ball mill to investigate the effects of grinding parameters such as mill speed, ball filling ratio, 2021年6月23日 The coarse ore from the primary crusher is mixed in the ore bin and then fed into the ball mill together with water for wet grinding By changing the frequency of the pendulum feeder, we can control the OptimalSetting for Ore and Water Feeding in 2020年7月6日 Ball mills are generally used for grinding stone materials such as coal, ore, and so on In general, Most ball mills have two grinding methods: wet grinding and dry Ball Mill, Ball Mill Manufacturer, Ball Mill Specification

ORE BALL MILLZK Ball MillRotary KilnGrinding

2023年7月28日 Ore ball mill can produce powder from various nonflammable and nonexplosive mineral materials with Mohs hardness below 93 and humidity below 6%, such as barite, limestone, kaolnite, ceram For this purpose, data sets of two laboratory ball mills with eight Ball Milling, Mixed Models and Particle Size Distribution ResearchGate, the professional network for scientistsTable 1 Specifications of industrial ball mills (PBM 2019年6月18日 The paper demonstrates the application of this methodology to optimize solids concentration in ball milling of an iron ore from Brazil The wet grinding Optimization of Solids Concentration in Iron Ore Ball Milling

Ball Mills 911 Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent Ore Grinding Ball Mill for gold/ magnetite/ copper / Iron Find product specification, supplier information and more at tradeKorea There are ladder liner and ripple liner and different specifications of steel balls in the chamber The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and Ore Grinding Ball Mill for gold/ magnetite/ copper / IronIndustrial Ball Mill Quartz Grinding Mineral Mills Grinding Ball Mill Specification 750t/h gold ore ball mill mining machinery $4,00000 $4,50000 Min Order: 1 set 13 yrs CN Supplier Contact Supplier Cement grinding vibratory vibrating ball mill specification grinding mills for sale in zimbabwe $8,90000 $16,90000 Min Order: 1 Simple Ore Extraction: Choose A Wholesale mill specification

Ultra Fine Grinding Mill Ultrafine Powder Technology

9 Application of ultrafine grinding mill – in ore field the capacity of the superfine powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30% Product Specifications Model: HGM80, HGM90, HGM100, HGM125, HGM168L Capacity: 0545t/h Max feeding size: 25 mm2021年12月18日 Joyal grinding plant ball mill gold ore cement ball mill price shanghai machinery 1 set 2 ton small ball mill for sale in south africa with factory price for gold processing diameter20150mm 3hrc5065 4materialsteel forged steel balls for ball mill specifications 1 high hardness 2 good wear resistance 3Ore Ball Mill Grinding Specification South Africa VCharty Grinding MillBall Mill This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow Ball Mill Used in Minerals Processing Plant Prominer

Estimation of Grinding Time for Desired Particle Size

2020年1月3日 22 Grinding Studies Two kinds of mills, BBM and LBM, were used to achieve the desired P 80 passing percentage of 150 μm with an acceptable range of hematite liberation (> 75%) at optimum grinding time The BBM is a standard ball mill having a length and diameter of 300 mm × 300 mm with smooth liner as shown in Fig 2A 2017年3月20日 An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied(PDF) Physicochemical Problems of Mineral Processing2023年9月5日 A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applications JXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and free operation training 【 Type 】 According to the Ball Mills Industry Grinder for Mineral Processing JXSC

Model 2400*3600mm Mining Ore Grinding Ball Mill

Features of Mining ore grinding ball mill 1 This type of Mining ore grinding ball millis a kind of traditional 1830x7000 dry ball mill, with rolling bearings (Babbitt metal bearing bushing seat) 2 Simple structure, and split installation 3 It Mechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision Ball Mill an overview ScienceDirect Topics2023年9月10日 Introduction: The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale ore beneficiation plant Dry grinding: suitable for materials that react with water, such as building stones such as cement and marbleBall Mill Mining Grinding Mill Mineral Processing

Ball Mill Design/Power Calculation 911 Metallurgist

2015年6月19日 The work index will also have a considerable variation across one ore body or deposit A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size technical data and specifications of ball mill – Gold Ore Crusher Technical Data – Cement mill, Cement plant, equipment, Cement making plant, machine, Cement mill price, Cement machinery wet ball mill grinder technical specification drawing Strongly recommend you to contact with us through online service! Meanwhile, you will get a Ball Mill Technical Specifications Crusher MillsBall Grinding Mill Specification (582 products available) Mineral Grinding Machine Different ball mill specification 900X1800 mm for sale $8,00000 $96,00000 Min Order: 10 setSimple Ore Extraction: Choose A Wholesale ball grinding mill

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made 2016年10月20日 Grinding Ball Rationing Determining the optimum size assortment of grinding balls for a makeup charge is a practical means of improving and 5) to lower retention time of ore in the mill An increase in throughput of the ball mill offers a big advantage Since total milling cost is the sum of fixed or indirect costs (capital investment Mining Engineering 1957 Vol IX 911 Metallurgist2007年10月19日 At Carajas, the new grinding plant was operational in 2002, with two ball mill lines followed by a desliming plant The closed circuit, wet grinding mills were designed to operate at 600% circulating load, in order to minimize the production of fine particles and consequently give increased recovery at the desliming plantSimulation of wet ball milling of iron ore at Carajas, Brazil

(PDF) Assessment of the Performance of Grinding Circuit for

2021年2月9日 Ball mill feed and product particle size distribution for survey 1, 2 and 3 Figure 8 to Figure 11 and Table 11 to Table 13 present the results for the size distributions and some key performance 2016年10月20日 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls Grinding Balls Rods 911 MetallurgistIf a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a Ball Mill (Ball Mills Explained) saVRee saVRee

Ore Crushing, Sand Making, Grinding Machinery Bellian

2023年9月9日 At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where 2023年8月14日 Model NO: MQG0918 Type: Ball Mill Motor Type: AC Motor Motor Power: 30KW Rotationl Speed: 2022r/min Application: MineRock Ore Ball Grinding Mill Machinery Heavy Mining Ball Mills With Specifications Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc Ball Mill Specifications, You Can Buy Various High Quality Ball Mill Specifications Products from Global Ball Henan Mining Machinery and Equipment Manufacturer Ball Mills

Iron ore pelletization ScienceDirect

2015年1月1日 In this hybrid grinding configuration, the energy efficiency of HPGRs is combined with the ability of ball mills to achieve high size reduction ratios Schönert (1988) pointed out that the success of the hybrid grinding mode depends on the efficiency of the HPGR in producing fractures within the product and weakening the particles that remain Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore Autogenous mills operate mechanically like ball mills; however, the media used for grinding differs Simply put, in autogenous grinding, the media is also the material that is being ground, whereas in other milling methods steel or Autogenous Grinding Mining FundamentalsThree series of grinding tests were performed using a laboratoryscale ball mill (Sepor, Los Angeles, CA, USA) with a volume of 5423 cm 3 operating at 66 rpm, which corresponds to 70% of its Table 1 Specifications of industrial ball mills (PBM )

The Selection and Design of Mill Liners MillTraj

Figure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolation2019年6月18日 demonstrates the application of this methodology to optimize solids concentration in ball milling of an iron ore from Brazil The wet grinding experiments were conducted in bench (025 m diameter) and pilotscale mills (042 m diameter), and surveys in a fullscale industrial (52 m diameter) mill It is firstOptimization of Solids Concentration in Iron Ore Ball